Application:

Full automatic premade pouch bagger, featured with rapid reaction, reliability and quick changeover, is ideal for a large variety of bag types and range.

Equipped with Z-shape bucket elevator and combination scale, it is widely applied to candies, microwave popcorn, cookies, nuts, rice, coffee beans, crops, peanuts, etc.

Technical Parameters:

| Model | QUA-8-200 | |

| Pouch Type | Stand-up bag, Gusseted bag, Handle bag,, Paper bag, Zipper bag | |

| Working Station | Eight working station | |

| Pouch | W | 80-220mm |

| L | 100-300mm | |

| Capacity | Up to 50 bags/ min (product property and filling range count) | |

| Filling Range | 0-3000g | |

| Dosing Systems | Multi-head combination scale, Linear scale, Volumetric cup, Auger filler, Piston filler, etc. | |

| Voltage | AC380V/50Hz, three phases (or customize) | |

| Power | 3.5KW | |

| Air Sourse | 0.4 CBM/ min (offered by the user) | |

| Machine’s Dimension | 2200x1850x1500mm | |

| Machine’s Weight | 1250Kg | |

Technical characteristics:

1. English and Chinese screen display, operation is simple.

2. PLC computer system, function is more stable, adjustment any parameters not need stop machine.

3. It can stock ten dispose, simple to change variety.

4. Sever motor drawing film, position accurately.

5. Horizontal, vertical temperature control, suitable for various of mix film, PE film packing material.

6. Packing type diversification, pillow sealing, standing type, punching etc.

7. Bag-making, sealing, packing, print date in one operation.

Processes:

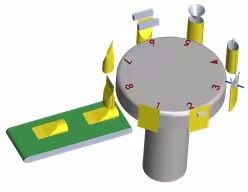

QUA-series pre-made pouch bagger can be clarified into 8 working stations and 6 working stations in terms of station amounts in one machine. Specifically, the whole processes are involved in the following stations:

| 1. | Pouch-picking Station (Required) |

| 2. | Date-printing Station (Required) |

| 3. | Pouch-opening Station (Required) |

| 4. | Material-filling Station-1 (Required) |

| 5. | Material-filling Station-2 (Optional) |

| 6. | Air-exhausting Station (Optional) |

| 7. | Matrial-detecting Station (Optional) |

| 8. | Sealing and Outputting Station (Required) |

Notes: Required Station is necessary to complete the package.

Optional Station is made as per customer’s request, such as zipper-opening device, dual dosing systems, dual sealing configurations, gas flushing device, air exhausting device, and so on.