Application:

Full automatic premade pouch bagger, featured with rapid reaction, reliability and quick changeover, is ideal for a large variety of bag types and range. Equipped with Z-shape bucket elevator and combination scale, it is widely applied to candies, microwave popcorn, cookies, nuts, rice, coffee beans, crops, peanuts, etc.

Technical characteristics:

●Assembled with multi-head combination scale to achieve precise material measuring and filling

●Assembled with Z-shape bucket elevator to achieve material lifting automatically

●SIEMENS PLC & HMI Touch Screen

●Equipped with frequency converter and SMC cylinder

●Full 304# stainless steel construction

●Wide application to various bag types and products

●Self-diagnosis: No filling and nor sealing when it is detected that the bag is not open or not open completely

●Auto-alarming if there’s something wrong with the air pressure or heating elements

●Auto-break occurs when the machine stops to achieve self-protection

●Bag width could be adjusted automatically by one button on the motor setup

●Oil-free vacuum pump to avoid pollution

●Customized zipper opening to avoid broken/ deformed bags

●Perfect sealing and excellent appearance to improve product level

●Conform to GMP and HACCP

●Applicable bag material: Laminated films, monolayer PE films, PP, and paper

Technical Parameters

| Model | QUA-6S350 | QUA-8S240 | |

| Pouch Type | Pillow bag, 3 & 4 side seal bag | Stand-up bag, Gusseted bag, Handle bag, Spout bag, Paper bag, Zipper bag (for option) | |

| Working Station | Six working station | Eight working station | |

| Pouch | W | 260-350mm 100-450mm | 80-240mm 100-300mm |

| L | |||

| Capacity | Up to 50 bags/ min (product property and filling range count) | ||

| Filling Range | 0-3000g | ||

| Dosing Systems | Multi-head combination scale, Linear scale, Volumetric cup, Auger filler, Piston filler, etc. | ||

| Voltage | AC380V/50Hz, three phases (or customize according to specific demands) | ||

| Power | 3.0KW | 3.5KW | |

| Air Sourse | 0.4 CBM/ min (offered by the user) | ||

| Machine’s Dimension | 2200x1850x1600mm | ||

| Machine’s Weight | 1700kg | 1800kg | |

Processes:

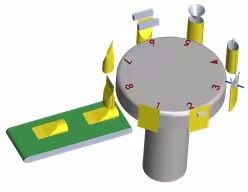

QUA-series pre-made pouch bagger can be clarified into 8 working stations and 6 working stations in terms of station amounts in one machine. Specifically, the whole processes are involved in the following stations:

| 1. | Pouch-picking Station (Required) |

| 2. | Date-printing Station (Required) |

| 3. | Pouch-opening Station (Required) |

| 4. | Material-filling Station-1 (Required) |

| 5. | Material-filling Station-2 (Optional) |

| 6. | Air-exhausting Station (Optional) |

| 7. | Matrial-detecting Station (Optional) |

| 8. | Sealing and Outputting Station (Required) |