Overview of Drip Coffee Bag Packing Machine:

- Principle of Operation:

- Drip coffee bag packing machines are designed to efficiently package individual servings of ground coffee for brewing.

- The machine operates by automatically filling, sealing, and cutting the packaging material to create individual coffee bags.

- Process Description:

- Ground coffee is typically loaded into a hopper or feeder at the beginning of the process.

- The machine then dispenses a precise amount of ground coffee into each bag, ensuring consistency in portion size.

- The packaging material, usually filter paper or non-woven fabric, is fed through the machine.

- The machine seals the edges of the packaging material around the coffee, creating a secure pouch.

- Additionally, some machines may include functionalities for attaching strings or tags to the bags for easy handling.

- Key Components:

- Hopper or Feeder: Holds the ground coffee and dispenses it into the packaging material.

- Sealing Mechanism: Ensures airtight seals around the edges of the coffee bag to maintain freshness.

- Cutting Mechanism: Cuts the packaging material to separate individual bags from the continuous roll.

- Optional Attachments: Some machines may include features for attaching strings or tags to the bags.

- Benefits and Applications:

- Drip coffee bag packing machines offer several benefits, including increased efficiency, consistency in portion sizes, and convenience for consumers.

- They are commonly used in the hospitality industry, including hotels, cafes, and restaurants, as well as for retail packaging of single-serve coffee products.

- These machines enable coffee producers to package their products in a convenient and hygienic format, appealing to consumers who value ease of use and freshness.

- Significance and Market Demand:

- With the growing popularity of single-serve coffee products and the demand for convenience among consumers, drip coffee bag packing machines play a significant role in the coffee packaging industry.

- They cater to the needs of both commercial coffee producers and individual consumers who seek hassle-free brewing solutions.

- The market demand for drip coffee bag packing machines continues to rise as coffee consumption trends evolve towards convenience and quality.

- Conclusion:

- Drip coffee bag packing machines streamline the packaging process for individual servings of ground coffee, offering efficiency, consistency, and convenience to both producers and consumers in the coffee industry.

Automatic packing machine for drip coffee bag & Steeped coffee bag

This machine matches most single pack coffee packages – Choice of automated coffee packaging

Various optional weighing & filling systems for coffee granule & coffee powder.

Max Speed

45 bpm

Inner Bag Size

Min

50 x 50 mm (2.0 x 2.0″)

Max

75 x 75 mm (3.0 x 3.0″)

Features

- Able to make drip coffee bag with an outer bag in one machine

- 304 stainless steel frame

- Mitsubishi PLC control

- Multi-Language HMI

- Automatic count & stop

- Photoelectric eye

- Guard door

- Date Printer

- Runs most film material

- Storage for 100 product recipes

Options

- Various filling systems for coffee, tea, herbal or powders

- Tear notch

- Materials infeed conveyors

- Package collator conveyors

- Metal detectors

- Checkweigher

- Bag deflators

Specifications

| Model | QUA-T300 |

|---|---|

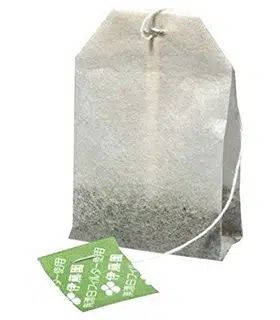

| Bag type | Drip coffee bag / Steeped coffee bag with envelope |

| Weighing Method | Auger filler / Multihead weigher / Volumetric cup filler |

| Packaging Speed | 30-45 bags/minute |

| Inner bag size | Length: 50-75 mm (2.0-3.0″) Width: 50-75 mm (2.0-3.0″) |

| Envelope bag size | Length: 85-120 mm (3.3-4.7″) Width: 75-95 mm (3.0-3.7″) |

| Recommended Size | Inner bag: 74 x 90 mm (2.9 x 3.5″) Envelope: 100 x 120 mm (3.9 x 4.7″) |

| Power | 220V 50-60Hz (Customizble) 3.7KW |

| Machine Weight | 650kg |

| Air supply requirement | 0.6m³/min |

| Machine Size | 1345 x 779 x 2262 mm |

Bag Types

Film Material

- The laminated film, laminated paper film, aluminum foil film

Optional Features

- Hanging hole, euro slot, carry handle, tear notch

Industries & Applications