Auto Glove Packaging Machine for All kinds of Gloves

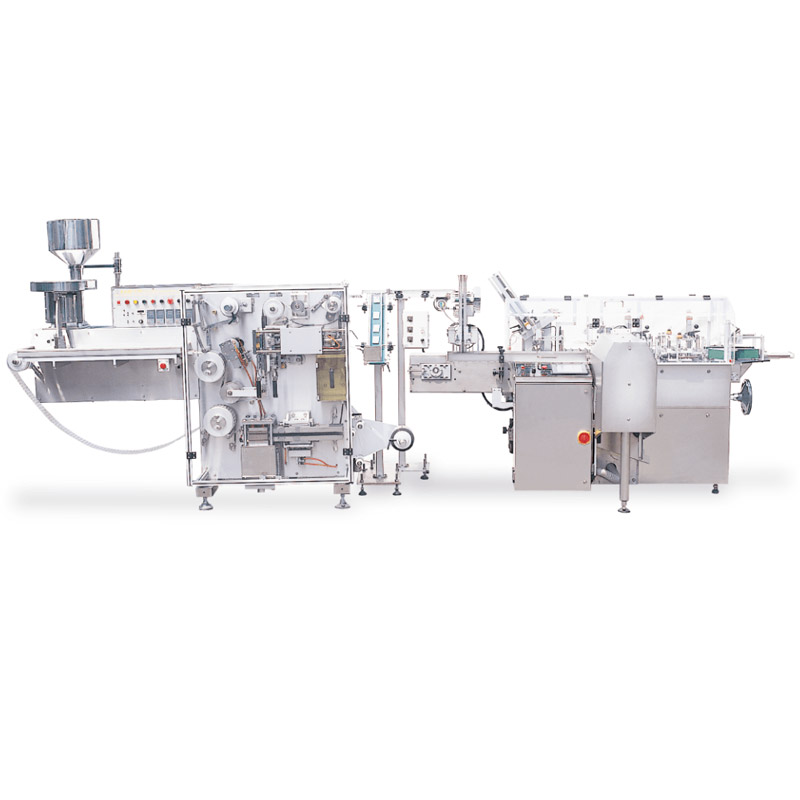

Auto Glove Packaging Machine. The auto glove packaging machine is a high-speed glove packing equipment for all kinds of gloves, such as dipped gloves, cotton gloves, anti-cut gloves, and rubber gloves. When using this machine, you only need to put the gloves on the feeding rail, the machine can complete the bag sealing, cutting automatically.

High quailty Flow Plastic Rubber Glove packaging machine

High quailty Flow Plastic Rubber Glove packaging machine. Plastic/Rubber/Mitten Glove packaging machine.One set of machine can be applicated to different kind of product via optional devices, such as air-filling device, feeding line, etc. Machine type: VT-160; Packaging speed: 30-200 Bag/Min; Packaging size: 30-160mm(Width) 65-400mm(Length ...

Absorbent Cotton Packing Machine - Cotton Roll Packing ...

Approx. Rs 2.5 Lakh / Set Get Latest Price. By making use of superior quality raw material, we produce horizontal flow wrap machine. Our machines are widely used in application areas including health care products like Disposable Syringe, Plastic Cutlery, Surgical Gloves, Absorbent Cotton & any solid items. The specifications and features are ...

Super-Efficient gloves packaging machine - flexpackmachines

Full Automatic Small Horizontal Surgical Face Mask Bottle Paper Cartoning Gloves Sealed Carton Box Packing Machine. Ready to Ship. $7,000.00 - $19,500.00. Min Order: 1 set. Shipping per piece: $37.00. Type: Multi-Function Packaging Machine. Packaging Material: Metal. Packaging Type: Bottles. Function: Laminating.

Automatic Glove Packing Machine for Knitted Gloves

The automatic glove packing machine is a new and high-speed glove packaging equipment for knitted gloves. When using this machine, you only need to put the gloves on the hand mold of the machine, and the machine can complete logo printing ( ink pad printing ), drying, glove taking off, bundling, bagging actions, realizing the automation of ...

Automated Packaging Equipment Solutions In Southern California

Our innovative automated packaging equipment solutions will help you reduce labor costs, resolve bottlenecks, and automate to increase capacity in any market. Learn more. Call: 800-894-7273

Automatic Glove Making Machine - flexpackmachines

The cost of a Automatic Glove Making Machine can vary widely depending on its size, capabilities, and complexity. Most of the price of Automatic Glove Making Machine ranges from US $ 2300 to $ 60000 per set. It's important to research and compare different models and features to find the best Automatic Glove Making Machine for your needs and ...

Glove Automatic Packing Machine Manufacturers & Suppliers

Glove Automatic Packing Machine Total 507 manufacturers & suppliers found with 1,521 products

Glove Making Machine - flexpackmachines

The cost of a Glove Making Machine can vary widely depending on its size, capabilities, and complexity. Most of the price of Glove Making Machine ranges from US $ 23000 to $ 990000 per Set. It's important to research and compare different models and features to find the best Glove Making Machine for your needs and budget.

Glove Manufacturing Process | Production, Automation and ...

During glove manufacturing, a ceramic hand-shaped mold called a former is conveyed through a dipping series at 60 ¡ãC. First, the formers are put through an acid and alkali wash followed by rinsing to remove dirt and residues. Then, they go through dipping, in which the first coat of a coagulant solution is applied.

- Phone+86-13502131345

- Emailjackie@fillingpackingmachines.com

- AddressWenzhou , China

20+ years experience in packing solution

20+ years experience in packing solution