Premium Glass water Bottle Filling Plant for the World of ...

CachedA glass bottle filling machine caters to this ethos by providing guests with a convenient and eco-friendly alternative to disposable plastic bottles. The touch of sophistication that glass imparts aligns seamlessly with the expectations of luxury clientele, contributing to an enhanced guest experience. Beyond the aesthetic appeal, the glass ...

Kärcher Futuretech Water Bottling Plant WBP 1300

CachedThe mobile WBP 1300 Water Bottling Plant enables fully automated bottle production from plastic preforms, and the PET bottles are subsequently filled with chlorine-free drinking water. With the WBP 1300, it is possible to produce 1300 1-litre bottles an hour. The system fills the bottles with treated drinking water directly on site without the ... Video Duration: 5 min

What's The Water Bottling Plant Cost - Your Bottled Water ...

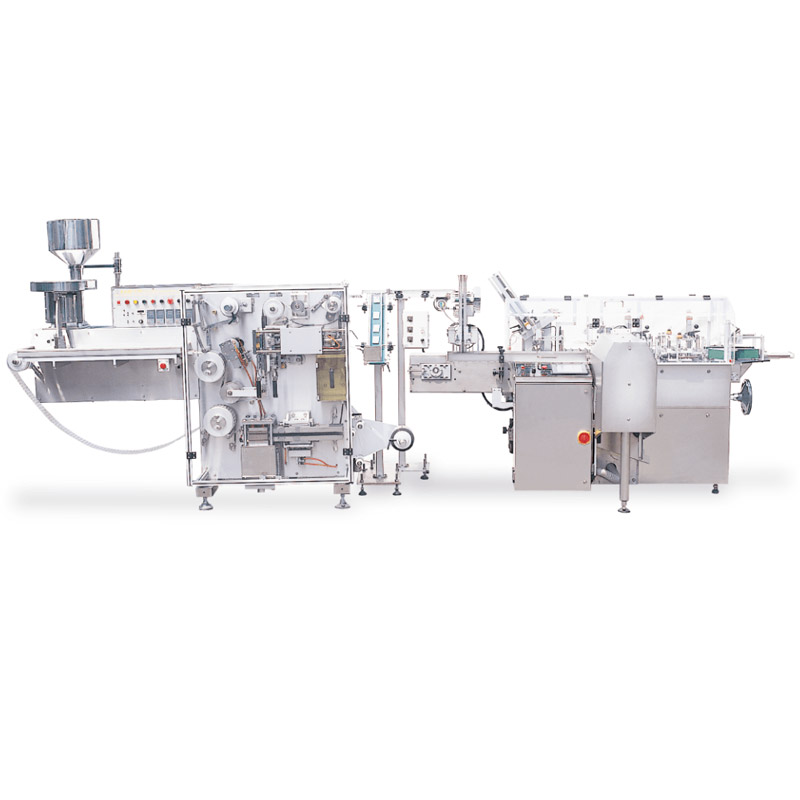

CachedWater Bottling Plant Launch ProcessWhat’s The Water Bottling Plant CostRo Water Treatment Equipment For Purified WaterBottle Blowing Machine For Plastic BottleFilling Machine & Packaging Line For Pure Mineral Water BottlingAuxiliary Equipment of Water Production PlantBottling Water Plant Cost ConsiderationsExpert Guidance on Startup Water CompanyIn Summary: What You Need to Know to Open A Water Bottling PlantWhile equipment purchase is critical, there are many important steps involved before buying machinery and starting production of bottled water. Here is an overview of the end-to-end process to start a water bottling plant: See full list on ibottling The major capital investments when starting a bottled water plant consist of: 1. Water Treatment System 2. Bottle Blowing Machine 3. Filling & Packaging Line 4. Auxiliary Equipment The table below summarizes estimated price ranges for equipment capable of producing 3000 bottles of 500ml purified water per hour: NOTE: The prices listed above are for... See full list on ibottling Sophisticated water treatment equipment is required to purify source water to meet bottled water quality standards. A typical mineral water bottling plant process includes: 1. Raw Water Tank – collects and stores water before treatment 2. Sand Filters – remove suspended solids down to 20 microns 3. Activated Carbon Filters – absorb chlorine, odors ... See full list on ibottling The bottle blowing machineforms plastic bottle preforms into consistent, custom PET bottles using precision molds. Main components include: 1. Infrared Preform Heaters – soften plastic preforms for blowing 2. High Pressure Air Compressors – supply compressed air for molding 3. Bottle Molds – form PET preforms into desired bottle shape 4. Cooling Sy... See full list on ibottling The water filling lineencompasses all steps from bottle washing to packaging: 1. Bottle Washer – clean interior surfaces prior to filling 2. Monobloc Water Filling Machinefill bottles with product water 3. Labeller – apply wraparound plastic or paper labels 4. Packager – group bottles into trays or shrink bundles 5. Conveyors – transport bottles be... See full list on ibottling Beyond core machines, auxiliary equipment is vital: 1. Air Compressor – provides compressed air for production 2. Chiller – supplies chilled water to cool equipment 3. Water Pumps – transfer and pressurize water 4. Electrical System – wires and controls for machines 5. Conveyors – connect different processing stages 6. Building Mezzanines – provide... See full list on ibottling When estimating the total startup budget for a mineral water bottling plant, key factors influencing costs include: Water Source – The required water treatment equipment complexity and expenses depend significantly on the quality of the source water. Clean underground springs or municipal supplies require less intensive processing compared to conta... See full list on ibottling While this guide covers the major steps, expenses and considerations when starting a bottled water business, expert input is highly recommended to avoid missteps and ensure the best outcome. As John Lau, project manager from iBottling states: “Launching a new bottled water brand involves substantial investments in specialized equipment and faciliti... See full list on ibottling Launching a successful bottled water plant requires in-depth planning, strategic equipment selection and securing adequate funding to cover all startup investments. While equipment purchases are a significant cost, many other operating expenses from product testing to marketing also demand budgeting. By understanding the complete process and costs ... See full list on ibottling

Water Bottling Equipment | Complete Bottling Lines by Norland

CachedSpecialty equipment designed for 1 gallon or 5.0 liter. Produce up to 1,000 (1 gallon) BPH. Simple to Operate. Manual or Automatic bottle-loading options. Complete Inline Machines Include: BR3000 Rinser for bottle rinsing. BF5000 XLT Filler for bottle filling. Automatic Capping Machine. Feed Table and conveyors.

Mini Mineral Drinking Water Filling Machine / Bottling Plant ...

CachedMini Mineral Drinking Water Filling Machine / Bottling Plant, For Small Factory, 1000-2000BPH 5.0 (1 review) 4 orders Zhangjiagang Sky Machine Multispecialty supplier 9 yrs CN Brand: AliVideo Duration: 45 sec

Bottle Filling Machines | High Efficiency Fillers | Bottling ...

CachedRinsing, Filling, Closing Bottle Filling Machines. Carbonation Techniques Ltd is the UK and Ireland agent for Ferrero bottling lines. Manufactured in Italy to suit your requirements, featuring 6 to 72 filling valves, Ferrero’s fillers give a production range from 1000 to 24,000 bottles per hour covering a wide product range.

What's The Water Bottling Plant Cost - Your Bottled Water Business

ibottling/how-much-you-need-to-invest-for-bottled-water-business-startup/See all results for this question

Water Bottling Plant Machines and Lines Supplier - FESTA

CachedThe official definition of “water bottling plant” is any machine and production line that produces bottled applied water. “bottled water” is defined as water stored in sealed containers in a bottling plant that is safe for human consumption. In some states of the United States, the government requires bottled water production plants to ...

- Phone+86-13502131345

- Emailjackie@fillingpackingmachines.com

- AddressWenzhou , China

20+ years experience in packing solution

20+ years experience in packing solution