Lube Oil Filling Machines - Revolutionizing Industrial ...

A typical lube oil filling machine operates systematically. Containers are first placed on the conveyor belt, which then guides them to the filling station. Here, sensors ensure proper alignment before nozzles dispense the predetermined amount of oil. Post-filling, containers are either capped automatically or moved to the next station for ...

Oil filling machine, Oil filler - All industrial manufacturers

automatic filling machine B¡¯BOOSTER TOP 780. bag bag-in-box for food. Throughput: 280 p/h - 720 p/h. Volume: 1.5 l - 20 l. Machine weight: 409 kg. High-speed automatic filling machine Modern and robust, with top performance and full automation, the automatic B¡¯BOOSTER filling machine allows independent high-speed ...

Smooth Operations: Lubricant oil filling machine

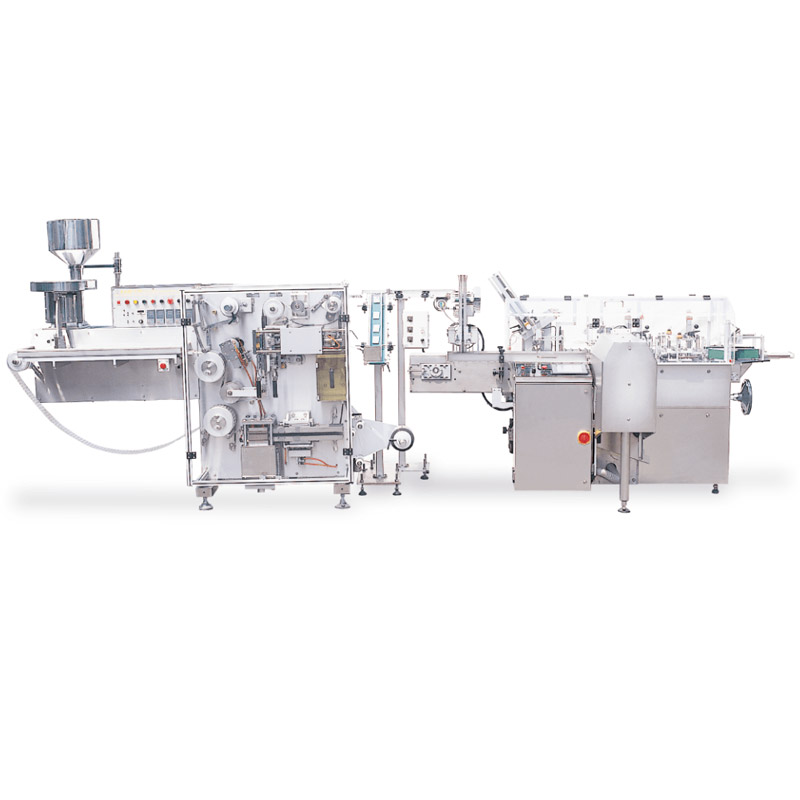

A lubricant oil filling machine automates the process of filling containers with lubricant oil. It consists of components such as conveyors, filling stations, capping stations, and labeling sections. Bottles are fed into the machine, filled with the desired quantity of lubricant oil, capped, labeled, and prepared for packaging. 2.

Lube Oil Filling Machine: Precision in Lubricant Packaging

A lube oil filling machine is a specialized industrial apparatus designed for the precise and efficient filling of containers, such as bottles or drums, with lubricating oil. This crucial piece of equipment is integral to the manufacturing process of lubricating oils, ensuring accurate volume dispensing and maintaining product quality.

Lubricants Filling Machines: Revolutionizing Industrial ...

Lubricants filling machines have embraced innovations like programmable logic controllers (PLCs), touch screen interfaces, and automation technologies. These advancements streamline the filling process, enhance accuracy, and reduce manual intervention. Efficiency and Modern Technology The integration of modern technology translates into higher ...

Oil Filling Machine - PESTOPACK

The rotary oil filling machines manufactured by Pestopack are fast, accurate and fully automatic, increasing productivity without compromising quality.We build each machine with your filling needs in mind, selecting the best components and adding as many filling heads as needed (from 8 to 60). Get The Latest Price Now.

Lubricant Oil Filling Machines | Petrochemical Filling | PACK¡¯R

A PACK¡¯R packaging machine offers optimal functionality and accuracy rates, so you are filling containers to the right capacity. With an automatic or semi-automatic oil filling machine, you can configure company operations to boost productivity and reach production goals. Your workers can easily make adjustments using the simple machine ...

Factory Price Lubricant Oil Filling and Capping Machine

Introduction: This type of machine can be used for fixed amount small package filling,straight line type filling, metical, electric, apparatus control of all sorts of viscous and no viscous,erosive liquid,such as plant oil chemical,liquid,daily chemical industry.It is rather simple and rapid to change items,the design is quite distinct,the property is Very advantageous,its appearance ...

Automotive Lubricants Oil Filling Machine - HZM Machinery

The automobile lubricating oil Filling and packaging machine is designed to complete the filling and packaging process for automotive lubricating oil on the production line. The primary function is to accurately inject lubricating oil into bottles, ensuring each bottle contains the correct quantity of lubricating oil.

Automatic Lube/ Lubricating/ Lubricant Oil Filling and ...

1.1 Suitable material: Lubricant oil £¬Lube oil £¬Lubricating oil£¬ very viscous. 1.2 This filling machine is a high-tech filling equipment controlled by . microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action. 1.3 Accurate measurement: adopt servo control system, ensure the

- Phone+86-13502131345

- Emailjackie@fillingpackingmachines.com

- AddressWenzhou , China

20+ years experience in packing solution

20+ years experience in packing solution