Instapak Speedypacker ¨C Sealed Air

The SEALED AIR? brand Instapak? SpeedyPacker system delivers expanding packing foam to high-volume packaging operations for quick, cost-effective product protection. The on-demand foam machine includes a versatile industrial-grade touch screen display that lets the operator select the optimum bag size and foam combinations for fast, secure ...

IntelliPack? On-Demand Foam in Place Systems | Pregis

On-demand foam or "foam-in-place" is made in real-time by combining two liquid foams in a bag or liner. The expandable foam packaging mixture rapidly surrounds the product creating a custom, protective mold. IntelliPack systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry.

SmartFoam Liquid Foam | BorderPak Packaging Solutions

INTELLIPACK FOAM-IN-PLACE OVERVIEW. IntelliPack? systems feature the most cost-effective, time-efficient foam-in-place packaging technology in the industry. The IntelliPack systems were designed with the operator in mind. The intuitive equipment design and responsive controls simplify the packaging process, reduce cost and increase productivity.

Efficient Liquid Foam Packaging Solutions | Alta Packaging

Cost Efficient. One of the most economical packaging materials available, foam can cut your costs dramatically ¨C without compromising product protection. Save Valuable Floor Space. Because foam expands up to 280 times its liquid volume, the equivalent of a trailer load of packaging material can be stored in two 55 gallon drums.

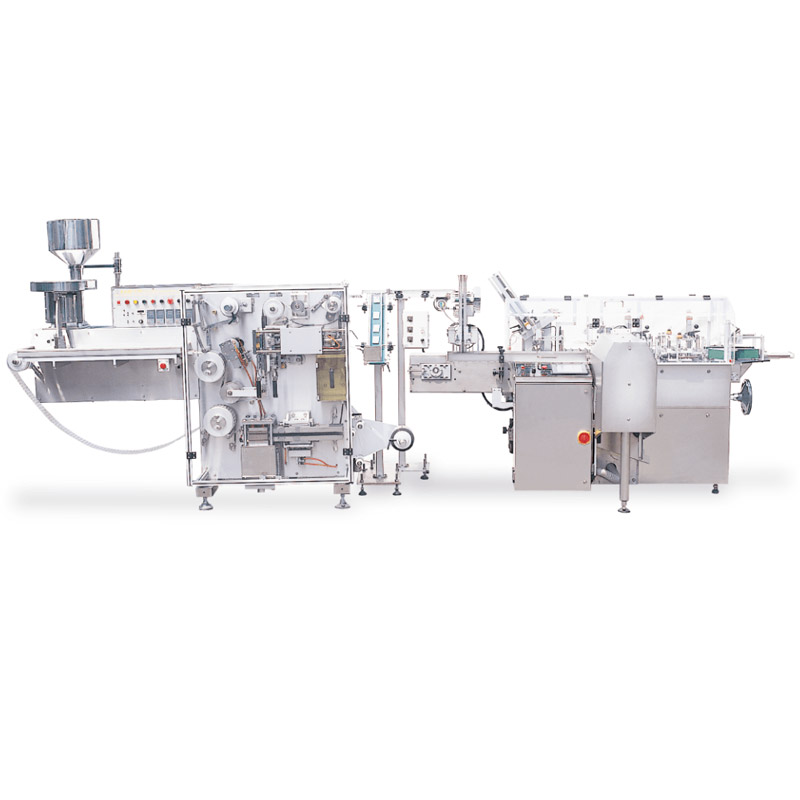

VERTICAL FORM FILL SEAL MACHINES - Unified Flex Packaging ...

This vertical form fill seal machine (VFFS) is ideal for low to medium production volumes, up to 7 lanes of stick packs can be packed simultaneously on this machine. Ideal for packing granular products like salt, sugar and suitable for food, hotel and catering industries. ¨C Up to 30 bags per min. ¨C Bag width: 1.5¡å max.

Foam Packing & Dispensing Equipment | EZ Flow Foam

Foam packing and dispensing equipment is designed to create and apply foam materials used for protective packaging and void filling in shipping and storage. This equipment automates the process of generating foam, ensuring consistent quality and efficiency in packaging operations. The foam used in this context is typically polyurethane or ...

Expanding Foam Packaging - Unipaq, Inc.

MD 50 Foam In Bag Machine Description. Our MD 50 Foam-In-Bag machine is designed for smaller items. Capable of producing 23 foam filled bags per minute, the MD 50 allows the operator to change bag sizes and foam-fill amounts based upon their packaging requirements. It¡¯s been designed to cut waste, improve efficiency and simplify operator ...

Foam in Place Equipment - Crown Packaging

What is Foam-in-Place Packaging? "Foam-in-place" (also known as on-demand foam packaging) leverages expandable foam that surrounds a product, creating a custom packaging solution that delivers a high-level product protection. On-demand foam is generated in real-time by combining two liquid components in a bag or liner, which is then place in a ...

Instapak? SpeedyPacker Foam-in-Bag System ¨C Sealed Air

Machine Size: Benchtop: 52 in W ¡Á 30 in D ¡Á 47 in H (132 cm x 76 cm x 119 cm) Floor model: 52 in W ¡Á 38 in D ¡Á 79 in-103 in H (132 cm x 97 cm x 201 cm-262 cm) Film Size: 12 in and 19 in W available. Production Rate: 21 12-in bags per minute, 50% foam-filled. Electrical:

Protective Packaging System - foam-in-place-systems

Foam-in-place packaging is an on-demand, custom solution that ensures the highest level of product protection through the shipping process. Made in real-time, foam-in-place systems combine two liquid components in a bag or film. The expandable foam mixture rapidly surrounds the product, creating a custom protective mold.

- Phone+86-13502131345

- Emailjackie@fillingpackingmachines.com

- AddressWenzhou , China

20+ years experience in packing solution

20+ years experience in packing solution